CAFS or Compressed Air Foam System Retrofits

Is it possible to retrofit my existing apparatus with a compressed air foam system?

There are a number of departments that have purchased new apparatus within the last 10 years or so that are still mechanically sound and worth investigating to see if a cafs retrofit is viable. There are no set rules for determining if cafs or compressed air foam systems are correct for your department. The same can be said for the consideration of doing a retrofit that will cost thousands of dollars and take your existing unit out of service for a period of time. That being said, let's look at some considerations that will assist you in determining the best route for your department.

As you can see there are a number of variables that can play into the "bottom line" when it comes to determining if a retrofit program is the correct way to go. It is difficult to give an average price, but for the sake of conversation I would venture a guess that on the "low end" a CAFS retrofit will cost $20,000 - 25,000. A good rule of thumb is an approximate cost of $7,500 - $10,000 per CAFS discharge point with the minimum cost of the $20-25,000 range already mentioned.

Now a word to the wise - DON'T let anyone that is not experienced in doing compressed air foam system retrofits attempt to "experiment" on your truck! The proper installation and integration of the cafs system is not only necessary but it can prevent unwarranted damage to your pump, electrical systems, and drive train! This is not one of the projects for the "shade tree mechanic" or those that have not been properly trained and factory authorized to do these types of critical installations.

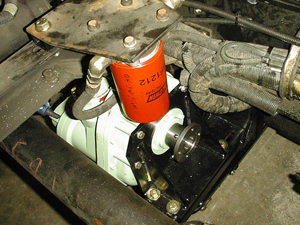

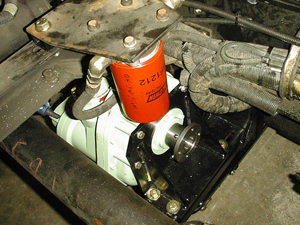

The best way to determine if a retrofit is right for your department is to review the considerations listed above and then contact one of the suggested links in my link page or included in this document. They will want as many details as possible and highly accurate digital photos to examine whether or not the process can be done. It may even include a visit by a factory or retrofit facility representative to further discuss and determine the viability of the end product. Again, cost is a determining factor - but so is quality of installation!

The following are suggested sites to visit for more information and expertise in assisting your departments needs and questions regarding retrofits.

W.S. Darley / Odin Foam - Probably the most experience in CAFS and retrofits.

(click on the logo to the left

to access CAFS retrofits)

Circle K Services / Midland, MI - Specializing in Fire Apparatus Repair Service

![]() (click on the logo to the left to access Circle K Service)

(click on the logo to the left to access Circle K Service)